Available Configurations:

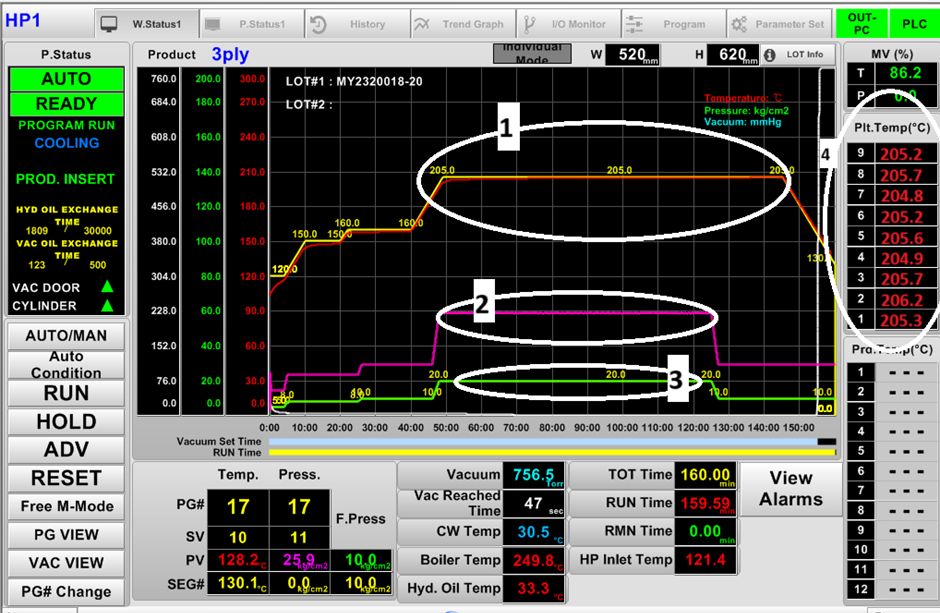

A robust PLC control package engineered for high‑temperature operations and precise multi‑zone heating. Built on Yokogawa hardware and designed for reliability, traceability, and operator safety across complex multi‑platen machines.

Independent, synchronized temperature loops per platen layer with auto‑tuning.

Components and logic designed for elevated operating temperatures.

E‑stop, door/guard monitoring, over‑temp cutoffs, and permissive logic.

Batch records, alarms, trend archives, and export for quality audits.

Clear setpoints, live trends, recipes, and maintenance screens.

Secure network access for diagnostics and support.

6 independent heating zones Shared or individual thermocouples per platen. Compact I/O footprint for small‑to‑mid systems

9 synchronized zones with grouped recipes. Intermediate throughput and energy balancing. Expandable for auxiliary sensors and interlocks

High‑density I/O for large platen stacks Segmented power stages to reduce inrush. Advanced trend dashboards and batch reports

Exact hardware and I/O counts are finalized during engineering based on load, sensor type, and site standards.

Yes. We adapt I/O, drivers, and actuation to your installed base where practical to reduce changeover time.

Yes. Operators can save, load, and audit recipes for different materials, with permission controls.

Optional secure remote access is available for diagnostics, updates, and training.

| PLC Platform | Yokogawa (model per project) |

|---|---|

| Control Loops | Per layer PID with auto‑tune |

| Sensors | J/K/N thermocouples or RTD (PT100/PT1000) |

| Actuation | SSR/SCR or contactor banks; segmented stages for 16‑layer |

| Comms | Ethernet/IP, Modbus TCP, OPC UA (as required) |

| HMI | Industrial panel; recipe management; multi‑language |

| Logging | Batch trends, alarms, CSV export |

| Safety | E‑stop, guard switches, over‑temp, permissives |

| Power | Per site; single/three‑phase options |

Composite curing and lamination Rubber, foam, and engineered materials Electronics and PCB pressing R&D and pilot line equipmentShared or individual thermocouples per platen. Compact I/O footprint for small‑to‑mid systems

P&ID and I/O lists

PLC & HMI programs

Wiring and panel drawings

FAT/SAT, manuals, and training